Aluminum Trailer Floor

| September 15, 2016 | Posted by Melinda under Uncategorized |

My trailer is 22 years old and over time the aluminum floor has undergone some abuse. Whether normal aging process, or from not being cleaned out regularly, the fact is that right now there is some corrosion and some pitting and I’d rather have the floor repaired later rather than sooner.

How best to protect the floor and prevent further damage?

My aunt did copious amounts of research on her older aluminum floor and came up with this protocol. I’m a little ADD and “trailer floor” isn’t on my list of things to obsess about this month, and so took her word that this was “best” and went for it.

It wasn’t all that strenuous, only a little tedious, and took the better part of two days because even in the central valley in 90 degree (It’s fall! It’s cooler!) temperatures, time is a critical element for something to dry.

Before doing anything. Had been sprayed down with water a couple days ago and let dry.

This product is applied to a dry aluminum surface. Lacking a working spray bottle I sorta splashed it all over. It did a remarkable job and so I got a little crazy and splashed some on the walls. Except I didn’t have enough to do ALL the walls, at least not evenly without a sprayer. So I squinted my eyes and kinda sorta tried to make it more even.

It foams when you splash/spray it on!

After spraying it off. Mmmm…Need to do a little spot treatment. Look at the difference between the first stall on the left and the wall under the divider!

I probably could have done more on the floor – ironically the part I was supposed to be paying attention to, but it wasn’t until the later steps when I was on my hands and knees I could see where I hadn’t gotten completely even coverage.

LOVED this aluminum cleaning stuff and could totally see keeping some in a spray bottle and using it to clean various walls as needed.

You can see in the back ground I’ve evened up some of the walls :p

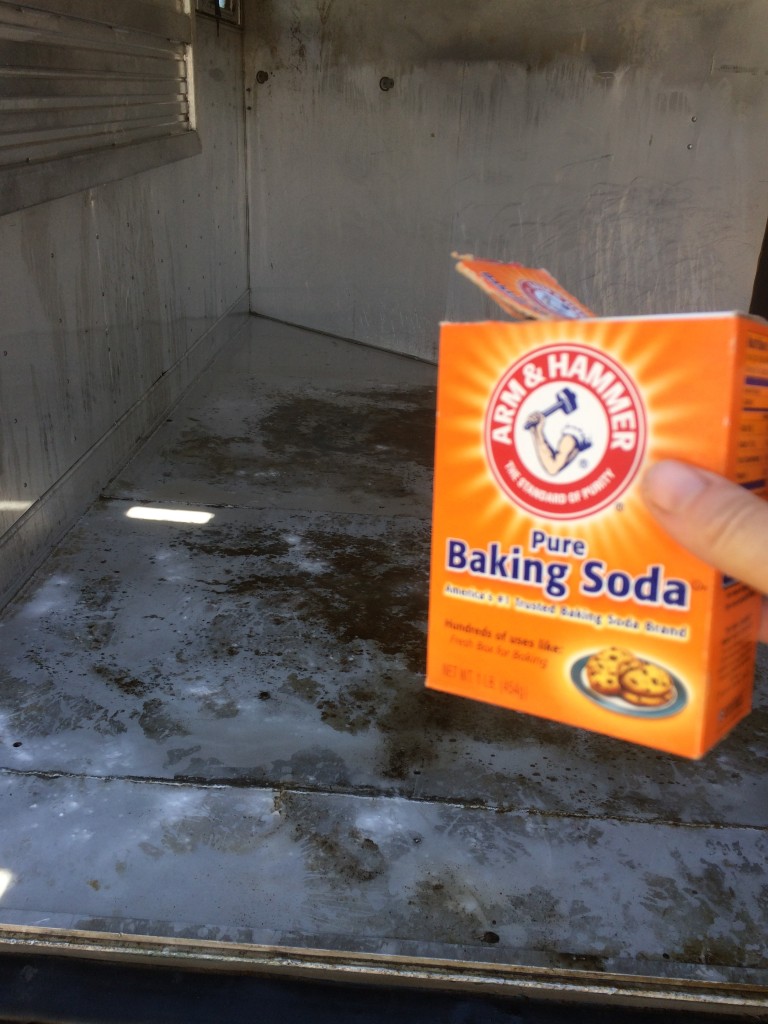

After copious amounts of rinsing I sprinkled baking soda over the top to neutralize the cleaning *just in case*. I didn’t actually bother finding out whether the cleaner I was using needed to be neutralized before my seal treatment, but it was easy enough to do, so I just did it. Didn’t quite have enough Baking Soda for an even liberal coating, but whatever. Prep instructions for Oxi seal said “weak baking soda solution” and I sorta swished everything around with a brush and water so good enough.

Next I let the trailer dry.

What it looked like after drying. Compare to very first picture. It looks so much better when it isn’t wet!

For “best results” wipe down the surface of the area to be treated with rubbing alcohol.

I used papertowels to wipe the floor off. That way I could see the amount of dirt was still on the floor and I could discard as soon as it got dirty (amazing at the amount of dirt still left on the floor after the number of rinses and scrubs it got!).

Good thing my trailer is old enough to drink.

Applying alcohol was the worst part. Everything else I used was fume free but the alcohol was practically suffocating. Pro tip – you need WAY less alcohol for this step than you think. Didn’t even use half of what I bought.

Last is applying the OxiX in thin layers. At least 3 coats are recommended. I thought the most efficient way to apply would be a small roller. I invested in a little 6 inch roller with 1/8″ nap for “mostly smooth surfaces” and a little plastic tray. The first layer wasn’t too hard to apply. The OxiX makes the aluminum look “wet”. However the next coats were hard to see where I’d been.

Two coats of OxiX applied. See how the floor “shines”? It’s unfortunate that it brings back the “wet” color of the aluminum, but everything is usually under black mats so whatever.

As I type this post I have two coats applied and I’ll definitely add a third, and maybe a 4th.

You *can* paint over the OxiX with paint, but I’m choosing not to do this. I want to be able to see my floor, and repeat this treatment if necessary. If I paint, it’s one more thing I’ll have to take off/prep in the future when I redo this treatment.

I’m not sure how long the OxiX will last. A couple of years? For a smaller floor plan this process wasn’t bad in terms of time, cost, and my attention span. I could see myself doing this every couple of years if warranted.

Thought the grooming bucket would be an interesting diversion of colors and textures.

If you are wondering about quantities, I used an entire gallon of aluminum kleen and about 1/3 gallon of the oxiX. I’m willing to sell my remainder oxiX if you are local (too hard to ship) so let me know if you have a similar project that you are doing.

OxiX has been sold.

Looks like this is another one of those post where the pictures show up correctly on the computer, and not when you look at it on a mobile device. Sorry.